SysAquaL/SysAquaH 25 to 125 have been designed and optimized to operate with R410A refrigerant fluid. They are of single refrigerant circuit type.

They are available in cooling only (SysAquaL) and heat pump (SysAquaH) versions.

Each versions consists of 11 sizes (25, 30, 35, 40, 45, 55, 65, 75, 90, 105 & 125) and covers a nominal cooling capacity range from 25.0 to 122 kW and a nominal heating capacity range from 26.9 to 120 kW.

All units are equipped with two scroll compressors fitted in tandem for adapting to partial system loads.

The general operation status of the machine is continuously under the control of an IHM controller.

The SysAquaL and SysAquaH units can operate without water tank, thanks to the lHM controller that implements an auto- adaptative control logic ensuring a total protection of the compressors at different load or water volume conditions. The minimum water volume requested in cooling mode is 3.5 litres per kW for application air conditioning and 10 litres per kW for application process.

In heating mode, 12.5 litres per kW are recommended in order to guarantee homogeneous temperatures during the defrosting cycles (comfort and energysavings). A fan speed controller can be also supplied as factory-fitted option to authorize the unit to operate in cooling mode at low ambient temperature.

SysAquaL and SysAquaH units can be supplied in several versions:

- STD (Standard) version : lncludes a low noise (LS) acoustical performance.

- XLN (Extra low noise) version : Obtained by the installation of acoustic box around compressors.

- HPF version : lncreases the static pressure.

Cabinet and structure

The cabinet and structure of the unit are of heavy duty galvanized steel.All galvanized steel components are individually painted by a special painting process before the assembly of the unit. This painting system performs a homogeneous protection to the corrosion.The painting is a polyester powder based type, coloured in RAL 7040.

The units SysAquaL/SysAquaH are suitable for outdoor installation, directly on the building roof or at the ground level.

Compressors

Each unit is equipped with two scroll compressors fitted on a rail and assembled together to form tandem compressors.

The compressors are then mounted on rubber pads in order to eliminate noise and vibration transmissions. The compressor motor shave a direct startup. Each motor is cooled by the refrigerant gas and is equipped with an overload protection.

A phase sequence monitor is supplied as standard.

Evaporator

The evaporator is consisting of a stainless steel plate heat exchanger insulated with closed cell synthetic foam. lt is protected by an antifreeze electric heater to ensure a good protection against freezing at low ambient temperature (-10 °C min.) when the unit is switchedoff.

Maximum working pressure is 10 bar at water side and 45 at refrigerant side.

Технические характеристики

| Производительность | ||

|---|---|---|

| Холодопроизводительность | 121,9 | кВт |

| Коэффициент EER | 2,63 | W/W |

| Тепловая мощность | 119,1 | кВт |

| Потребляемая мощность, нагрев | 45,46 | кВт |

| COP | 2,62 | W/W |

| Общие данные | ||

|---|---|---|

| Потребляемый ток | 103,5 | A |

| Частота | 50 | Hz |

| Количество фаз | 3N~ | |

| Напряжение (номинальное) | 400 | В |

| Параметры звука | ||

|---|---|---|

| Уровень звукового давления на расстоянии 1 м, наружный блок | 83 | дБ(А) |

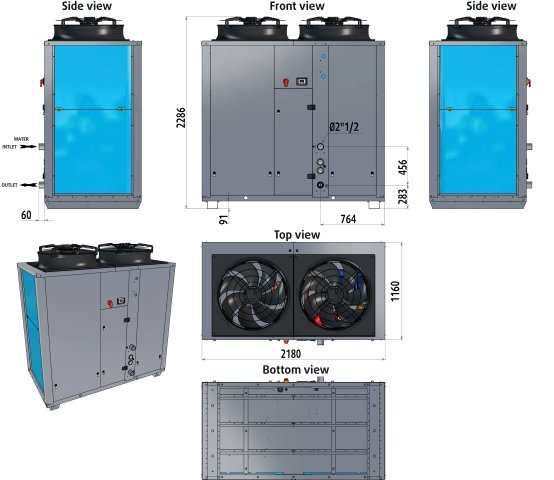

| Размеры и вес | ||

|---|---|---|

| Вес | 1 050 | кг |

| CF/ IMAGE | ||

В настройках компонента не выбран ни один тип комментариев