Features

The new SysAer have been designed and optimized to operate with R410A refrigerant fluid.

Energy class A, Ecodesign 2021 ready - applicable from 2021

High SEER and SCOP

They are available in cooling only and reversible versions.

The range consists in 10 sizes (SR55, SR65, SR80 ,SR95, SR105, SR120, SR140, SR160, SR190 and SR210) and covers a nominal cooling capacity range from 49 to 216 kW and a nominal heating capacity range from 49 to 211 kW

2 circuits for the entire range to optimize performances at part load, and avoid cold draught during defrost mode. The range SysAer is provided with 2 compressors from sizes SR55 to SR140, and 4 compressors from sizes SR190 to SR210.

These configurations which allow up to 4 capacity stages give an immediate return on investment.

The general operation status of the machine is continuously under the control of an IATC controller

Cabinet and structure

The cabinet and structure of the unit are of heavy duty galvanized steel. All galvanized steel components are individually painted by a special painting process before the assembly of the unit.

The units SysAer are equipped with double skin panels as a standard to prevent insulation fiber entering into the building and harmful build-up of bacteria or contaminants. It also ensure better thermal insulation.

Great accessibility to internal components for service operations.

Removable drain pan.

Aeraulic configuration

The SysAer is provided with blast and return fans, PLUG FAN type with an AC motor or with an EC motor, Low Pressure or High Pressure according to the configuration selected by the customer

Economiser with 2 dampers

The factory-mounted economiser with 2 dampers is available with the R1, R2 and R4 configurations.

The control program for the economiser is optimized to use the biggest possible amount of outdoor air, in order to save consumption of the compressors, and thus energy.

Energy recovery systems

RECO : energy recovery on the exhaust air

The factory-mounted economiser with 3 dampers, is equipped with an EC plug fan return fan as a standard and is available with the R1 and R2 configurations.

The economiser increases the partial load operation of the compressors and improves the seasonal efficiency thanks to a proportional-action control function.

The economiser with 3 combined dampers, with proportional modulation of the outdoor-recycled-extracted air allows an extraction up to 100% of the total air flow (in equivalent quantity to the intake of outdoor air).

It provides real energy savings by regulating the air renewal.

TRECO : thermodynamic energy recovery between Fresh air and Exhaust air

This option is available only on the SysAer equipped with 3 dampers (not compatible with the FRECO system).

This thermodynamic system for recovering energy between the exhaust air and fresh air is delivered entirely mounted and factory tested. It is composed of an independent refrigeration circuit and a dedicated control.

This energy recovery system allows real energy savings

FRECO : food refrigeration heat recovery

The SysAER provided with a FRECO system uses the heat generated by the condensers of the refrigeration systems of a supermarket as a free source of heat.

Heating

• The SysAER can be equipped, according to the specifications of the customers, with an additional heating system. This equipment is installed and tested in the factory.• Hot water coil

• Electric heating

• Gas burner

Control

A factory-programmed direct digital control (the IATC) handles and optimizes the operation all throughout the year, emphasizing comfort and the saving of energy.

The IATC regulates the heating and the cooling according to the desired ambient temperature, controlling the cyclical operation and the rotation of the compressors, as well as the de-icing, overload protection, high and low pressures, compliance with the requirements for minimum ventilation and the fan mode, continuous or intermittent.

Compensation for the summer-winter ambient temperature and a min/max ambient temperature setting are provided as standard.

A system for building management provided by another supplier can communicate via ModBus with a card of the RS-485 type as an option, on the user interface. The parameters of the SysAER are then transmitted and can be modified from a remote monitoring and troubleshooting station.

In case several SysAER are installed (in zones or groups whether or not different), it is possible to display the parameters of each unit with only one interface for the entire installation. The principle consists in connecting all of the units in parallel, using a single pLAN bus (proprietary protocol), while connecting the graphics interface to a master controller. This IATC will centralize certain operating modes, such as the 'occupied/unoccupied' mode.

Технические характеристики

| Производительность | ||

|---|---|---|

| Холодопроизводительность | 209,7 | кВт |

| Коэффициент EER | 2,82 | W/W |

| Тепловая мощность | 217,3 | кВт |

| Потребляемая мощность, нагрев | 66,25 | кВт |

| COP | 3,28 | W/W |

| Общие данные | ||

|---|---|---|

| Потребляемый ток | 158 | A |

| Частота | 50 | Hz |

| Количество фаз | 3N~ | |

| Напряжение (номинальное) | 400 | В |

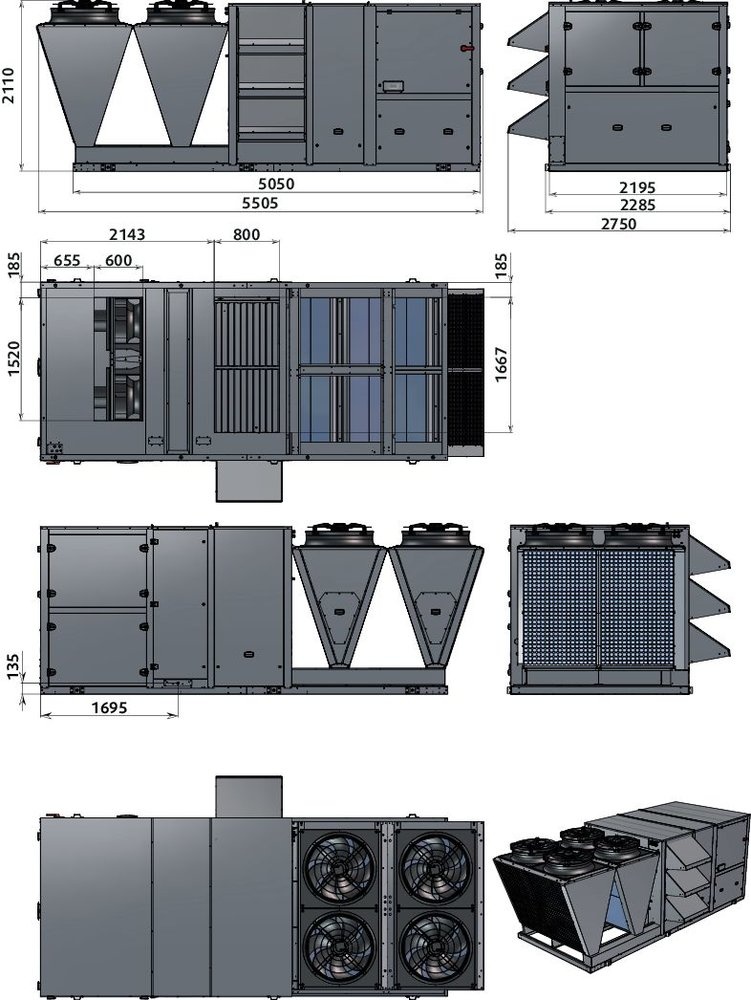

| Размеры и вес | ||

|---|---|---|

| Вес | 2 935 | кг |

| Length | Total | 5 505 |

| Floor | 5 050 | |

| Width | 2 285 | |

| Height | 2 100 |

В настройках компонента не выбран ни один тип комментариев